Glamor Lighting - Professional Decorative Lighting Supplier & Manufacturer Since 2003

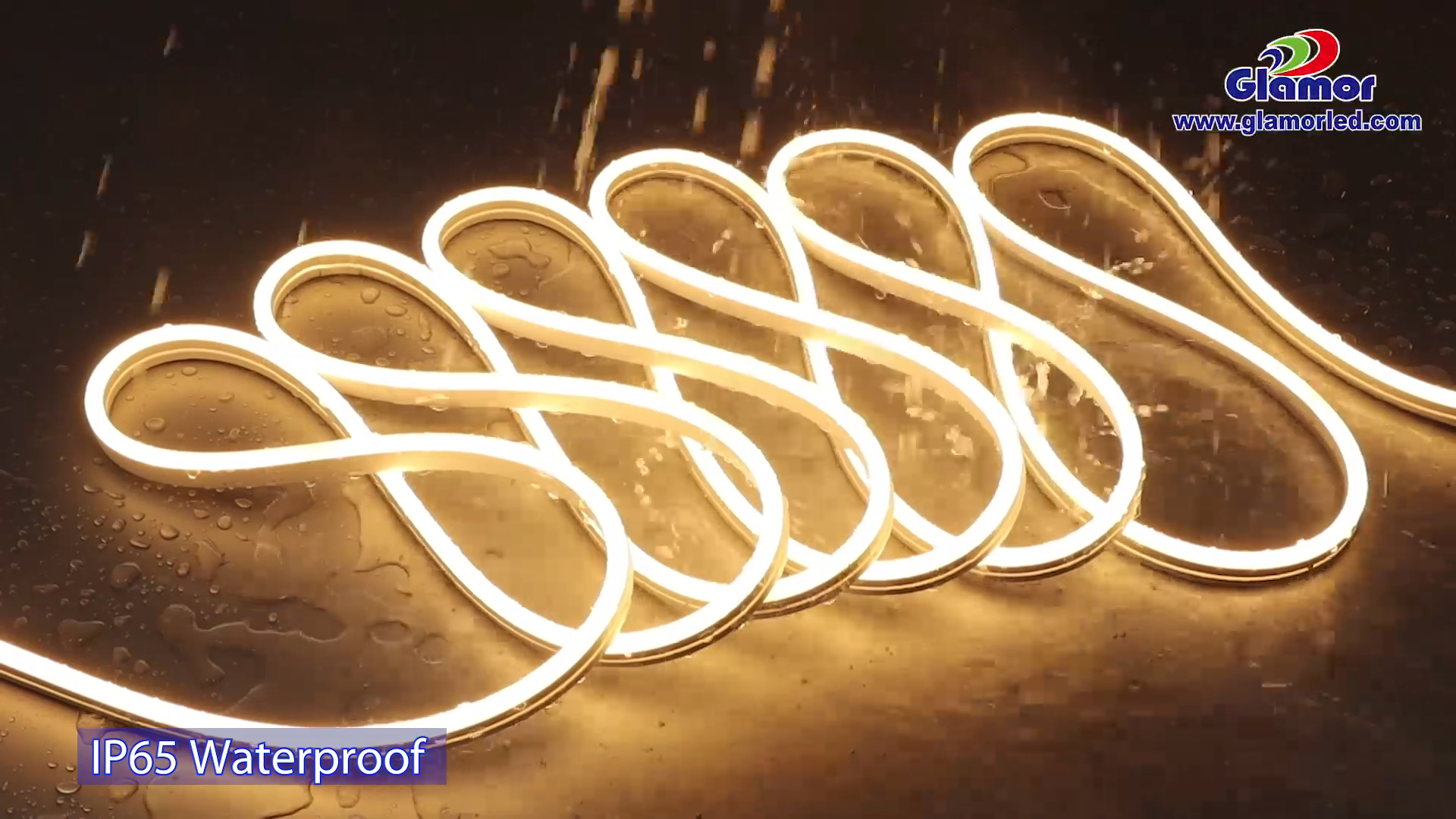

Glamor Hot Selling LED Neon Flex Ip65 Waterproof Neon Flex Light

We will conduct a waterproof test video of LED neon flex and let's see how it works.

Our LED neon flex with certificates of CE CB SAA IP65 RoHS REACH UL CUL ETL

Benefits Of Ip65 Waterproof Led Neon Flex

The benefits of IP65 waterproof LED Neon Flex are manifold, making it an exceptional choice for both indoor and outdoor applications. This innovative lighting solution combines aesthetic appeal with robust functionality, featuring a flexible design that allows for intricate installations in various settings—from vibrant signage to architectural highlights. The IP65 rating ensures resilience against dust and water ingress, providing peace of mind when exposed to elements such as rain or humidity; this durability extends the lifespan of the neon flex while maintaining its luminous glow even in challenging environments. Moreover, LED Neon Flex is energy-efficient, consuming significantly less power compared to traditional neon lights without compromising brightness or color vibrancy. Its lightweight nature facilitates easy handling and installation processes, perfect for decorative projects that demand versatility. Additionally, the low heat emission characteristic not only enhances safety but also opens up creative possibilities where conventional lighting solutions might pose risks.

How Long Does Led Neon Flex Last?

LED Neon Flex is renowned for its impressive longevity, typically lasting anywhere from 50,000 to over 100,000 hours of illumination. This exceptional lifespan significantly surpasses traditional neon lighting and other forms of incandescent or fluorescent options. The durability of LED Neon Flex stems from its advanced technology, which utilizes solid-state components that are less susceptible to breakage compared to fragile glass tubes used in classic neon signs. Furthermore, the energy-efficient nature of LED Neon Flex not only reduces power consumption but also minimizes heat generation, contributing further to its longevity and reliability even in demanding environments. With proper installation and maintenance, users can enjoy vibrant colors and consistent performance from their LED Neon Flex installations for many years without major degradation in brightness or color quality.

Led Neon Flex Installation

Installing LED neon flex involves several steps. Here's a general guide to help you with the installation process:

1. Planning:

✦ Determine the desired placement of the LED neon flex and measure the area where it will be installed.

✦ Consider factors such as power source availability, mounting options, and any specific design requirements.

2. Power Source:

✦ Locate a suitable power source near the installation area.

✦ Ensure that the power supply meets the voltage and wattage requirements of the LED neon flex.

✦ Follow local electrical codes and safety guidelines when connecting the power supply.

3. Mounting:

✦ Decide on the mounting method for the LED neon flex, which can include surface mounting, recessed mounting, or suspending.

✦ Use appropriate tools to securely attach the mounting hardware to the installation surface.

✦ Ensure the mounting surface is clean and free from any debris or moisture.

4. Cutting and Shaping:

✦ Measure the length required for your LED neon flex and cut it accordingly. Some LED neon flex products may have designated cut points.

✦ Use sharp scissors or a utility knife to make clean cuts. Avoid cutting through the wires inside the neon flex.

✦ If necessary, shape the LED neon flex to fit curved or angled surfaces by bending it gently. Refer to the manufacturer's instructions for any specific bending guidelines.

5. Wiring:

✦ Connect the LED neon flex to the power supply using appropriate connectors or soldering methods.

✦ Make sure to match the positive (+) and negative (-) terminals correctly to avoid damaging the LED neon flex.

✦ Secure the connections properly with insulation tape or heat shrink tubing to prevent any electrical hazards.

6. Testing:

✦ Before permanently securing the LED neon flex, test the installation by plugging in the power supply.

✦ Confirm that all sections of the LED neon flex are working correctly and producing the desired lighting effect.

✦ If any issues are detected, double-check the wiring connections and troubleshoot accordingly.

7. Securing and Protecting:

✦ Once the LED neon flex is functioning properly, secure it firmly in place using clips, brackets, or adhesive depending on the chosen mounting method.

✦ Consider adding additional protection, such as silicone sealant or outdoor-rated enclosures, if the LED neon flex will be exposed to harsh weather conditions or moisture.

It's important to note that every LED neon flex product may have specific installation instructions provided by the manufacturer. It's recommended to refer to these instructions and follow them closely to ensure a safe and successful installation.

FAQ

Yes, sample orders are warmly welcome for quality evaluation. Mixed samples are acceptable.

Advantages of Glamor LED Neon Flex Suppliers

4.Our main products have certificates of CE,GS,CB,UL,cUL,ETL,cETL,SAA,RoHS,REACH

About GLAMOR LED Neon Flex Manufacturers

Get In Touch With Us

If you have more questions, Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

QUICK LINKS

PRODUCT

If you have any question, please contact us.

Phone: + 8613450962331

Email: sales01@glamor.cn

Whatsapp: +86-13450962331

Phone: +86-13590993541

Email: sales09@glamor.cn

Whatsapp: +86-13590993541